|

Author

|

Topic: Beaulieu Take-Up Problem.

|

|

|

Paul Browning

Phenomenal Film Handler

Posts: 1006

From: West Midlands United Kingdom

Registered: Aug 2011

|

posted March 23, 2015 03:32 PM

posted March 23, 2015 03:32 PM

Yes Andrew that is my point, look at the picture's when rob gets them, the pin is the replaceable bit, how much ware has it caused the mating part. I would think if this is a part wittner keep, they are well aware of this, and will probably sell the mechanism as a complete item, or else they would be stuck with not being able to sell the other parts. I have not had this apart so its merely a stab in the dark, the exploded view is ok for knowing what goes where, but you have to get the part, physically in your hands, you find a possible better way. If the parts prove to be cheap enough, then there is no point reinventing the wheel.

| IP: Logged

|

|

Rob Young.

Phenomenal Film Handler

Posts: 1633

From: Cheshire, U.K.

Registered: Dec 2003

|

posted March 23, 2015 03:46 PM

posted March 23, 2015 03:46 PM

Guys, this is just brilliant support from you all, thank you.

I will try to get some detailed images up tomorrow.

Andrew, what do you reckon is the best way to contact Wittners; email or phone? It's a while since I was in touch with them, but I will see if they can provide the parts.

Paul, I think it is worth looking into what has gone wrong here with regard to perhaps making better replacement parts.

We are taking mm's. The small ratchet part seems to be made up from 3 parts, the ratchet plate plus two "prongs" which are fixed onto it. I'm not an engineer, but I reckon if I can get you guys detailed enough photos you will know how it has been made and maybe know how to make a better version!

I'm concerned as to why it has been able to come out of position and wear itself down...although maybe Beaulieu engineers didn't count on 35+ years of use!!

Pics tomorrow, and thanks again guys, you are the best!

| IP: Logged

|

|

Andrew Woodcock

Film God

Posts: 7477

From: Manchester Uk

Registered: Aug 2012

|

posted March 23, 2015 03:48 PM

posted March 23, 2015 03:48 PM

No you're right Paul,I haven't needed to start looking at any of these one way clutches on these either on mine yet.Most of the mechanical parts on these have a very robust reputation. They are not known for any particular mechanical weaknesses,so this fault on Robs I suspect is quite a rare one.

I know the friction washers need replacing after years of use but this is only to be expected given that these are a "designed in" consumable wear item. The wear to these is seriously accelerated if you use your machine to clean your films with as this does put a lot of strain on both the motor and the rest of the drive chain but they should last many many years if you use the machine only as intended.

As Rob says, maybe the slippage is due to the two Ratchet Plates not being sandwiched together under the normal spring pressure as they normally would and therefore perhaps a gap for the pin to disengage has been created.

If the spring pressure has not been exerting the correct pressure on the Ratchet Plates then I suppose it would result in what Rob is currently witnessing.

We will just have to wait and see, all will become apparent I'm sure once Rob gets around to posting the photos of the parts and the wear on them.

One thing I can say for certain, is that if Wittners can and will sell these parts you can bet your bottom dollar that they won't be cheap, but at least they will be brand new originals.

Rob, I have only ever contacted Wittners by e mail and then you could submit your photographs alongside the part numbers.

They would then advise which parts (if any) they could provide you with to carry out the successful repair.

As you say Rob, no need to press the panic button just yet and start re inventing the wheel at this stage! Lol ![[Wink]](wink.gif)

Incidentally, the best and by far most robust method of achieving a one way drive in engineering mechanisms, I have found are these

http://stieberclutch.com/

They come in all different sizes and they tend to outlive the bearings that are fitted on the same drive shaft.

Dependant on which way around they are fitted to the shaft, governs which rotation the unit locks or freewheels, so one unit does for either rotational requirement.

These are very very durable mechanisms indeed which also run silently in both directions unlike a traditional ratchet mechanism.

--------------------

"C'mon Baggy..Get with the beat"

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

Paul Browning

Phenomenal Film Handler

Posts: 1006

From: West Midlands United Kingdom

Registered: Aug 2011

|

posted March 24, 2015 07:52 AM

posted March 24, 2015 07:52 AM

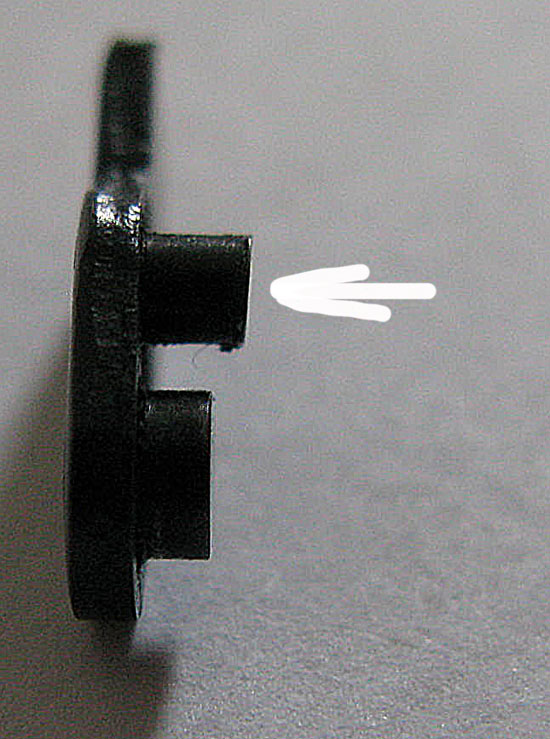

Hi Rob, good clear pictures mate, ok, the pin provides the drive in one direction, and slip out of the hole to allow it to travel in the opposite direction. The pin is warn at an angle, which is warn so much that its longest point from the base cannot now latch at the lower part of the hole, so riding up the angle and slipping, does this sound right so far?, can you determine which way round it travels, in relation to the pin angle.

| IP: Logged

|

|

Rob Young.

Phenomenal Film Handler

Posts: 1633

From: Cheshire, U.K.

Registered: Dec 2003

|

posted March 24, 2015 08:45 AM

posted March 24, 2015 08:45 AM

Hi Paul, I believe the worn part is supposed to fit through the hole on part 18 all the time.

In reverse mode, this holds the pin one way, so that the ratchet itself is out of an engaged position.

In forward, the hole pushes the pin the other way so that the ratchet swings to engage position.

So it is supposed to be always protruding through and engaging with the hole on part 18, regardless of direction; just swinging one way or the other.

It has clearly been allowed to rotate around disc 18 and wear down; possibly by coming out of position during rewinding.

"The pin is warn at an angle, which is warn so much that its longest point from the base cannot now latch at the lower part of the hole, so riding up the angle and slipping"

Yep, sounds right. It just about protrudes enough, but is now worn so much as to just about catch the sides of the hole on 18, but keeps slipping.

| IP: Logged

|

|

|

|

|

|

Paul Browning

Phenomenal Film Handler

Posts: 1006

From: West Midlands United Kingdom

Registered: Aug 2011

|

posted March 24, 2015 02:01 PM

posted March 24, 2015 02:01 PM

Rob, that's how I see it mate. Looks too over engineered to do what its doing, for sure. OK here's my thoughts on this, if it was my projector and I was faced with seeing this, I would modify the driving gear first, and if space would allow fit the one way roller bearing that the GS uses in there, modify the spindle slightly, give it a plain shaft, not with the flat drive on it,( as its not needed), use the retaining circlip to hold it in place. Fixing the bearing to the gear would allow to lock in clockwise directing to take up, and free wheel to rewind. This works very well on the Elmo, yes I know the gear attached to it splits, but the bearing works faultlessly otherwise, and its doing the very same job, as this over complicated mechanism does. What you think Rob, its an alternative to what's coming at you from wittners ?. I've now measured the clutch bearing that fits the Elmo, although smaller in diameter this would fit into the existing toothed gear at the back of the beaulieu, depth is also good, would need to sleeve up the roller bearing to approx. 14mm to fit good, just the shaft bit now, will measure and get back on here. May not need to modify this shaft with the flat on after all, now will the roller take the extra torque and inertia from those big reels ?, maybe.

[ March 24, 2015, 03:28 PM: Message edited by: Paul Browning ]

| IP: Logged

|

|

Andrew Woodcock

Film God

Posts: 7477

From: Manchester Uk

Registered: Aug 2012

|

posted March 24, 2015 03:29 PM

posted March 24, 2015 03:29 PM

Hello again Rob,

If you are wanting to request original spares the website address I used to do all of my ordering and enquiring was,

Service@wittner-Kinotechnik.de

I would exhaust that avenue first if this was my machine.

There are easy ways to repair the Ratchet mechanism I think, if I am seeing it correctly, but if it were me, I would just want new exact parts to replace the worn and damaged ones with first and foremost.

Then I would have a go at carrying out a repair on what you have if the first choice isn't an option.

Finally as Paul says, fitting a "Formsprag " clutch arrangement in a modified shaft arrangement is certainly a possibility but for me, this is not a common enough fault on these projectors to justify any lack of trust in the original set up.

It just appears that at some stage the spring tension has been lost or forced back into its completely compressed state on the Ratchet Support Plates and therefore a gap has been allowed to form in between the normally sandwiched plates. This would then allow the Ratchet itself to become dislodged from its otherwise reliable location hole and travel slot in it's normally forced together, sandwiched state.

Also remember that these parts along with the others along the shaft form a dual function mechanism.

Yes it is a one way ratchet mechanism but because of the springs and friction washers etc, it is also a clutch. On any "fixed" method of drive, something has to give if the clutch becomes overloaded so as not to burn out the motor or cause damage to the inner gear mechanisms.

With this in mind, these original parts may just be the safest way to protect the rest of the mechanism in cases of the clutch being overloaded, for example film cleaning during rewinding etc etc.

Finally Rob, what is the condition of the screw 2.5 dia x10mm lg item 14 mounted to item 13, which I believe is what the ratchet engages with as it protrudes through the hole on item 18 when assembled correctly?

[ March 25, 2015, 10:42 AM: Message edited by: Andrew Woodcock ]

--------------------

"C'mon Baggy..Get with the beat"

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Andrew Woodcock

Film God

Posts: 7477

From: Manchester Uk

Registered: Aug 2012

|

posted March 25, 2015 04:36 PM

posted March 25, 2015 04:36 PM

Look at what i wrote on march 24th 03:29 please Rob. It concerns part 14

I have to say Rob,that having looked at your photo's a few times over as well as the exploded view drawing from the manual, that if parts 14 and 21 all appear unscathed, if you just filed the worn pin flat and chambered the top edge on it again slightly,I see no reason why when re assembled correctly again with the correct spring tension re applied, why this assembly would not function perfectly well again.

If the Ratchet screw (14) protrudes through the hole on the plain ratchet plate as it should by around 6 to 9mm I am guessing, then the two pins on the actual ratchet are still in tact, only the moving pin not the pivot pin has wear to it and even then, fractions of a mm just to one side.

So long as it protrudes sufficiently to fill the curved slot to its full depth, and it appears it would, then it is doing its job in just the way it was designed to do so.

It appears to me, just from looking at the photos that once item 14 enters in between the two sandwiched ratchet plates, the entire mechanism should work as intended.

Let me know your thoughts on this Rob please and also please update me on the condition of parts 14 and 21.

On your first photo Rob, showing the Ratchet Support Plate and the Ratchet assembled together, the Ratchet Support Plate appears to be the opposite way around to the drawing as though the Ratchet itself (18) should be mounted into the plate from the opposite side. Is this correct Rob and if so, why have you photographed it with the Ratchet in the support plate the wrong way around?

[ March 26, 2015, 03:48 AM: Message edited by: Andrew Woodcock ]

--------------------

"C'mon Baggy..Get with the beat"

| IP: Logged

|

|

|

|

|

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Confused]](confused.gif)