|

Author

|

Topic: Replacing lamp holder on Beaulieu 708el.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Andrew Woodcock

Film God

Posts: 7477

From: Manchester Uk

Registered: Aug 2012

|

posted September 25, 2015 10:18 AM

posted September 25, 2015 10:18 AM

As Steve points out Rob, anything other than a soldered joint can be something of a compromise. It is of course entirely up to yourself how you go about it.

I just wanted it as good as the manufacturer did the job in the first place. For this I found the procedure I outlined to you Rob, both simple and the best for having no, or as few soldered joints as possible.

At the end of the day, heavy current or not, the lamp on both legs only terminates with spade connections.

These themselves are not necessarily the best way to make an electrical join, so as long as the work is carried out to a high standard, I don't envisage you having any issues Rob.

If you do decide to go down the terminal block route to facilitate quick and easy future change outs, May I suggest you use bootlace ferrules on each of the cable ends.

These use an excellent crimping method and the red ones are the correct size for this cable.

Guaranteed no stray ends and a decent connection to the brass screws using these.

[ September 25, 2015, 05:24 PM: Message edited by: Andrew Woodcock ]

--------------------

"C'mon Baggy..Get with the beat"

| IP: Logged

|

|

|

|

Steve Klare

Film Guy

Posts: 7016

From: Long Island, NY, USA

Registered: Jun 2003

|

posted September 25, 2015 11:26 AM

posted September 25, 2015 11:26 AM

That's the funny thing about these: the ratings are kind of strange if you are thinking purely electrically. I use one that is rated at 250V and 750W without a current rating, before I bought it I assumed the socket was only good for 3 Amps: a ton less than the 10 Amps a 150W, 15V EFR lamp needs.

I talked to the guy I was buying it from and he said the power rating is really a lot more a function of temperature, not exactly an electrical rating. You can't just divide the wattage rating by the voltage rating.

So I've rarely to never seen one with a rated current: something I'm not really comfortable with. Probably if I was more towards the 250V level and only needed 3 Amps (or even less) I might not care.

What I like about the ones I have is they are certified by a safety agency (Underwriters Laboratories here in the US), which means samples have been run through rigorous testing and found not to cause unsafe failures (as in short circuits and bursting into flame!).

The other sockets weren't up to the task and were at the least potentially damaging to my projector, at the most dangerous.

So I would say you are looking for more than the wattage of your lamp, more than the voltage (no problem for us) and bonus for agency certs.

[ September 25, 2015, 12:41 PM: Message edited by: Steve Klare ]

--------------------

All I ask is a wide screen and a projector to light her by...

| IP: Logged

|

|

Andrew Woodcock

Film God

Posts: 7477

From: Manchester Uk

Registered: Aug 2012

|

posted September 25, 2015 03:06 PM

posted September 25, 2015 03:06 PM

The one you've ordered Rob is the correct identical ones used by Beaulieu. They work perfectly fine Rob.

I will look at the manufacturer data sheet for the exact technical ratings for you.

Obviously over time, as we all know, the spring brass terminals in the insulation block do expand due to the temperatures these are subjected to.

It will after so many years, require changing again depending on how long and how often you use your machine for, but so far, I've never changed one out twice.

I think it's fair to say also, I probably use my projectors more than most so they do last a very long time before problems with arcing and damaged / welded lamp pins or premature lamp failure becomes an issue again.

Update:

The Bender & Wirth lamp holders are rated as follows:

250v 12.5a 250 degrees celsius Max.

Your projector lamp draws a current of 10A Rob, so well within spec.

[ September 25, 2015, 05:20 PM: Message edited by: Andrew Woodcock ]

--------------------

"C'mon Baggy..Get with the beat"

| IP: Logged

|

|

|

|

|

|

Rob Young.

Phenomenal Film Handler

Posts: 1633

From: Cheshire, U.K.

Registered: Dec 2003

|

posted October 18, 2015 08:49 AM

posted October 18, 2015 08:49 AM

Well, it's done but I think Andrew may not like it!! ![[Roll Eyes]](rolleyes.gif)

I can't thank you enough, Andrew, for your instructions on how to change the lamp holder as though it were new from the factory, but in the end, I'm sorry, but I chickened and did this;

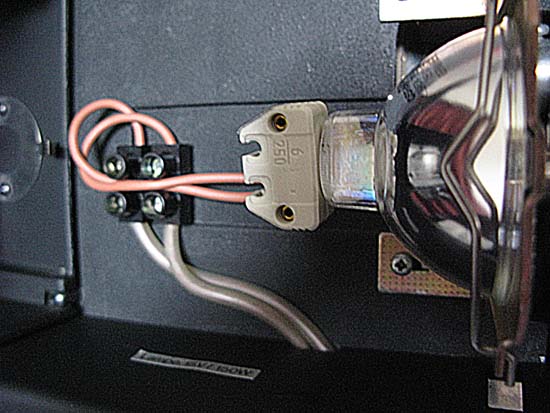

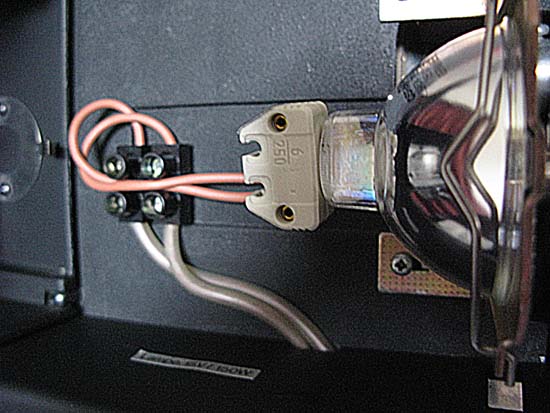

The connector block is a 15 amp rated, high temperature type.

It is held onto the projector body with a strong, heat resistant glue (105 degrees +).

I reckon this way, it will be very easy to replace the lamp holder again if it should ever need doing.

The ends of the new lamp holder wires were pre-soldered and it was fairly easy to cut and trim the wires from the old holder. With care and a magnifying glass, I'm sure I've achieved solid connections.

I've run it for about 4 hours now and the image is as bright, if not slightly brighter than the old lamp connector, which had become oxidised and lamps were somewhat loose fitting.

Plus no overheating of wires or connector block.

I'm pretty pleased. Thanks to all for their help and again, I'm sorry that I don't have your courage, Andrew, to take things apart!

![[Smile]](smile.gif)

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic

![[Roll Eyes]](rolleyes.gif) ), so I will order both parts from him.

), so I will order both parts from him.![[Smile]](smile.gif)

![[Wink]](wink.gif)