|

Author

|

Topic: More GS Trouble

|

|

|

Paul Adsett

Film God

Posts: 5003

From: USA

Registered: Jun 2003

|

posted October 25, 2006 06:42 PM

posted October 25, 2006 06:42 PM

Patricia,

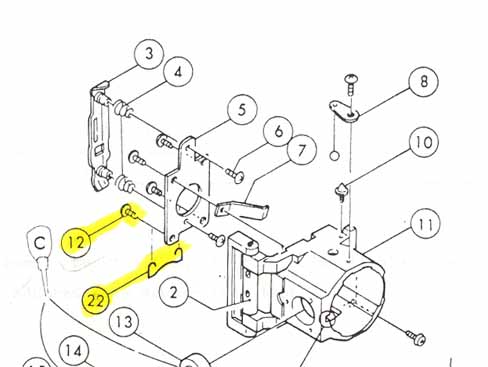

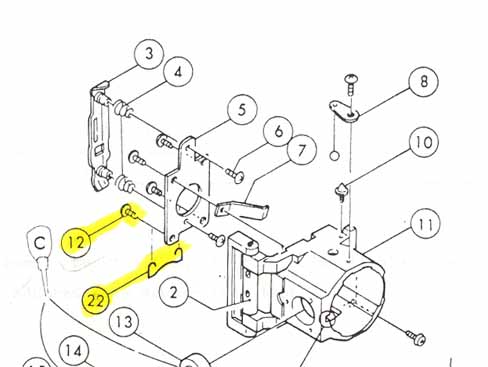

Here is what I believe is the area of concern, based on your description:

The wireform (22) should lie perfectly flat as shown in the picture. It should not be hitting anything, either in the open or closed position of the swinging lens mount.

Make sure of the following:

1. The wire form is shaped and located just like in the picture, and is not loose.

2. The wireform is centered and is not hitting the spring loaded pressure plate (3)

3. Use the two screws (12) to loosen and center the wireform so that it does not hit pressure plate (3), then tighten up both (12's).

When you close the hinged lens assembly, it clicks into place as a result of the conical pin (10) engaging a shaped spring steel plate bolted to the main chassis (not shown above). This is perfectly normal, and is unrelated to any issues you may have with the little wireform below the lens holder, as described above.

--------------------

The best of all worlds- 8mm, super 8mm, 9.5mm, and HD Digital Projection,

Elmo GS1200 f1.0 2-blade

Eumig S938 Stereo f1.0 Ektar

Panasonic PT-AE4000U digital pj

| IP: Logged

|

|

|

|

|

|

|

|

|

|

Paul Adsett

Film God

Posts: 5003

From: USA

Registered: Jun 2003

|

posted October 26, 2006 10:34 AM

posted October 26, 2006 10:34 AM

Thank's for setting me straight Kev. This is an area where evidently the adjustments are fairly critical, and a little knowledge is dangerous, probably not suprising in view of the complexity of the GS design. Presumably, those gram tension guage load values in the diagrams are there for a reason! (incidentally, where would you get those things?).

From Patricia's description, it sounds like the wire spring on her machine is way out of position. Hopefully, she will now have enough information to start to correct the problem. But as you say, if she could post a photo it would help a lot.

--------------------

The best of all worlds- 8mm, super 8mm, 9.5mm, and HD Digital Projection,

Elmo GS1200 f1.0 2-blade

Eumig S938 Stereo f1.0 Ektar

Panasonic PT-AE4000U digital pj

| IP: Logged

|

|

Patricia Carpino

Junior

Posts: 21

From: East Hartford, CT, USA

Registered: Oct 2006

|

posted October 26, 2006 07:12 PM

posted October 26, 2006 07:12 PM

HELLO: GENTS ...

Yes I do understand the gravity of this situation!

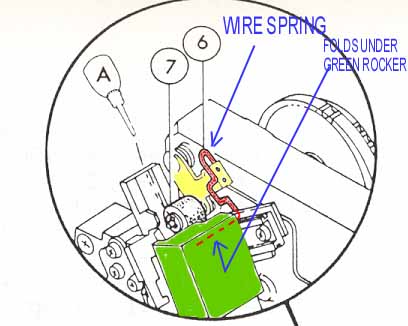

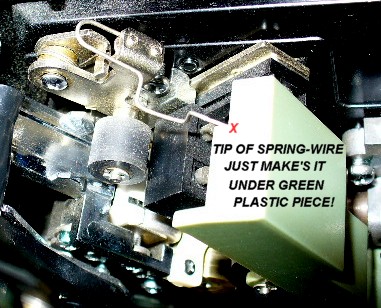

Now, with new wisdom , I will walk slowly from this point on. I have to find my digital cam., here someplace, and I will post a shot prior to the "operation". I have temp. bent the spring away from the lens and "dipped" it under the "green plastic PART, but just making it....just enough to contact it, so it will work and press down the roller properly, and the projector's sound is a tad+ better for sure! (BEFORE IT WAS BENT STRAIGHT OUT AND WOULD COME INTO CONTACT WITH THE BOTTOM OF THE LENS EVERY TIME I SHUT THE DOOR. THIS WOULD IN TURN "FREEZE THE ROLLER" AND MY FILM WAS "LOOPING PROPER" BUT WITHOUT THE ROLLER "PINNING" IT DOWN) Now I need to Post a good Picture because I understand this has to be done properly:

1) I NEED TO KNOW IF MY SPRING IS "LONG ENOUGH" AND HAS NOT BEEN BROKEN TO SHORT TO MAKE THE BENDS PROPER TO REACH UNDER THE GREEN PLASTIC PIECE. (I CAN'T SEE IN THE MANUAL ANY VIEW FROM THE "TOP" SHOWING THE ACTUAL SPRING BEND UNDER THE GREEN PLASTIC ITEM.) I UNDERSTAND THE TWO "TINY SCREWS" ARE FOR ADJUSTMENT OF THIS SPRING. BUT HOW MUCH IS NEEDED TO GO UNDER I DON'T KNOW ...IT MUST JUST SIT THERE BECAUSE THERE IS NO GROVE OR SLOT FOR IT? (I.E... I WOULD GUESS IT WOULD BE BENT UNDER AT A 45 DEG. ANGEL SO TO SPEAK.)

2) I ALSO NEED TO KNOW IF THE "GREEN PLASTIC PIECE" IS ADJUSTABLE VIA THE "TWO SCREWS" IN THE BASE OF THE PIECE, AND IF THIS CONTROL'S THE "RESTING OR STOP" POSITION OF THE PIECE? I THINK I HAVE TO ADJUST THIS GREEN PLASTIC AT "STOP PROJECTON" POSITION PRIOR TO THE 1.5 TO 2MM ADJUST OF THE ROLLER PART ..CORRECT? (ILL POST PIC ASAP!) THANK YOU ALL SO MUCH!

Pat Carpino

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Michael De Angelis

Phenomenal Film Handler

Posts: 1261

From: USA

Registered: Jul 2003

|

posted November 04, 2006 03:30 PM

posted November 04, 2006 03:30 PM

Patricia,

It is difficult to believe that there were not

any sprocket damage or splices in your 16mm IB Tech

film, which caused it to go wacky.

But as it did happen, it could be a cause of twisted,

warped or shrunken film.

Please note that when projecting 16mm IB Tech Film,

you should turn the film on the take up reel in the opposite

direction.

What I mean to say is that as the film comes off

the last roller or sprocket wheel, it shoul not

follow with the film sprockets on the same side as they

entered the projector. They should instead rest on the

take - up reel in the opposite direction. Thus,

the film has a slight reverse twist between the take - up

and before it rests on the reel. This exercise helps the film.

Paul had written:

[/QUOTE] Patricia, clean up that machine so it looks like Kev's! For super 8 your projector has to be cleaned before every show, otherwise you will get oxide dust particles all over your films, and scratch them as well. It should look like it just came out of the shipping box. Wipe the whole film path with a q-tip moistened with furniture polish then use an air can to blow out any remaining debris. Use alcohol on the rubber rollers and brass sound capstan. And lube your films for smooth, quiet running.

I trust Paul's opinion implicitly,

but I am myself very wary in using furniture

polish on the GS 1200.

His theory in using furniture polish is

correct. Because Furniture Polish - ie: 'Pledge'

has silicones in the ingredients. It is the silicones

that make the furniture shine with glory.

The irony is that, it is these same silicones that are harmful

to wood furniture finishes.

Silicone can be helpful in making the film less

abrasive and with less noise as it passes through

the gate. It can also prevent wear to the metal parts

and to the film.

Many years ago, there was a product known as: Surfaset.

It was manufactured as a liquid, and was also sold

impregnated in flannel clothes.

To many collectors

and film users, this was very good.

There are some film users and hobbyists that do not

reccommend Surfaset or any silicones, because they

believe that too much - which can also be very little,

will migrate onto switches and electronic parts causing

damage.

I do not wish to sound contradictory, but I use Surfaset

and have the last of a limited supply left over.

I do not believe that it is made any longer.

This product was specially made for vinyl records

and film. I also use it very sparingly.

Also, Film Renew is a recommended film cleaner,

conditioner and lubricant. It can be placed on the

surface of film and also wiped along the guide rails

or metal surfaces of the projector.

It is not a very slow drying, and neither a fast drying

cleaner because the properties remain on the

film for a considerable amount of time.

Basically, Film Renew is a Stoddard Solvent.

This is akin, but not the same as paint thinner

becuase paint thinner is also a Stoddard Solvent.

Many new prints that are being made today

have qualities in the surface of the film that when

you touch it, you can feel how smooth and lubricated

it already feels. That is the best part about today's film

prints. On the other hand, it is always the stripe

that needs lubricating.

Film Guard is a very slow drying cleaner and

lubricant. Many hobbyists picked up on this product,

because it had been used by 35 mm users.

It remains wet on the surface of the film. This is helpful

with films that have a lot of surface wear, because it hides

the blemishes. On the other hand, if you have tape splices

or tape that holds down the ends of the film, it will soften

the splices. A softened tape splice, is one that no longer

appears clear, but now has a milky appearance.

People will even soak - warped or buckled films in Film renew,

and then reverse the back wind the films and let them set

for several months - the films will go back to their original

flat shape. Remember: if prints are soaked and if they have tape splices,

the splices will appear milky and will soften and fall apart.

Back to where I left off: after soaking, collectors will leave the film on the reel -

'tails out' and against the buckle or twist to flatten the

film to its original shape, after it has been soaked and it

is allowed to air dry prior to projecting again.

This also recalls to what I mentioned earlier about

turning the film on the take - up reel when projecting

IB Tech prints. As you know, IB Tech prints are black & white

stock prints, with color dyes imbibed into the stock of the film.

There have also been some lubricants that when left on the film,

have also migrated onto the plastic reels, causing damage to the

plastic reel. Some of these fast drying cleaners were notorious

for damaging the plastic reels. I have experienced this,

and do not recommend fast drying cleaners.

About using alcohol on the rubber rollers? That is your call.

Use it carefully.

Some manufactures, never suggested alcohol use on rollers

of tape players or tape recorders, because of fear in drying the

rollers - and causing them to harden.

See what they say at Radio Shack about this. That's if

you get a person that knows their stuff. Otherwise,

they just employ nut jobs that don't know anything - let

alone what time it is to go home and lock - up.

As a matter of fact, some of these employees should be locked-up.

![[Wink]](wink.gif)

If this is note is offensive in any way - I apologize.

It was just meant to be kept simple and not to offend anyone.

The members of this Forum are terrific.

Good luck with your collecting.

![[Smile]](smile.gif)

Michael

--------------------

Isn't it great that we can all communicate about this great

hobby that we love!

| IP: Logged

|

|

|

|

Michael De Angelis

Phenomenal Film Handler

Posts: 1261

From: USA

Registered: Jul 2003

|

posted November 05, 2006 11:54 PM

posted November 05, 2006 11:54 PM

Patricia,

I own a few reels with IB Tech. But have not used this technique

of twisting the film, when projecting films.

I for one, am a little faint of heart. So, I do not twist the IB Tech film.

Because I am afraid that something can go wrong during the program.

A fellow 16mm collector Ray Faiola, uses this technique,

in twisting the IB Tech film onto the take-up so it lays in the

opposite direction. Ray stated this on the 16mm Film Talk forum,

and I also noted this at one of his screenings a while back.

I am just sharing the information.

In a similar fashion, as I stated earlier - I use

Surfaset, and Paul uses Furniture Polish. - They both

have silicone in it.

Many people refrain from using any silicone based

treatment any where near their films and projectors.

Some people, another friend in (New Britain, CT ) wishes that he

had Surfaset to use on some of his 16mm Agfa prints,

because the Agfa's seem to chatter a little bit, and Surfaset

would help this issue with some of his prints.

This goes back to what I had mentioned earlier about prints made

today have a quality that they seem almost as if they are lubed

from being released.

Which brings us to another dimension - how are films treated and

stored?

Acetate film needs to breathe. It also needs to remain

in a stable enviornment that is not damp or subject to high

temperature and high humidity. Sometimes sealed plastic

cans are not good for film. The cardboard boxes are always better.

How are films placed on a reel?

Is the reel in good shape or poor shape?

As Chip Gelmini mentioned a while back, he

takes great care in mounting the films on quality

take up reels. He has also devised a method to

ensure proper take-up during his programs.

In the long run, it affects the film and the quality

of the sound and projection.

For the most part, many film libraries, store the film

in an upright or vertical postion. The debate

ensues, that films placed in a horizontal or flat - stacked

position, is better for film storage.

Another idea worth noting is that it is best to

rewind the films on rewinds. Either Hand or Electric.

I prefer Hand rewinds. It permits me to control the wind

onto the reel. Not too tight, and not too loose.

If a film is wound too loose, it can buckle and warp.

If it is wound too tight, then it does not have the tolerance

to breathe properly.

It is also good to lubricate the films, and store them so that

they can air dry prior to projecting. If wound too tight,

then they will remain wet. If they are stored wet,

then they can buckle and warp.

It is not good to store films away when they are wet.

Yes, too much left on the film, is not good to store films away wet for a full year

or more.

When you had asked do I store the film away with a twist until the next show?

I have a few B&W titles that I have soaked, rewound in the opposite

direction against the twist, and permitted them to air dry.

I have then gone back and watched the film, and found that it had

either taken the 'egg shape' out of the take-up on the reel or

it had lessened or flattened the twist in the film that caused it to

pop the focus out of sharpness on the screen. These problematic

films have taken several attempts to remedy, and I have left these

black and white titles back wound for a few months and a few years.

I have not used Film Guard. But only have purchased films

from collectors that have used this product and have sold

me their films with this product on it.

The Properties of Film Guard are very slow drying.

It is a good product, and I found that the splices

look milky and no longer clear. It makes me wonder

if the splices will last? Film Guard unlike Film Renew,

dries very slow. Film Renew dries slow, but not as slow

as Film Guard.

Another thing about the Film Guard is that

the film is lubricated so well, that you do not

even hear it going through the projector.

I don't remember the name of one product that

Derann sold at one time, but when applied,

it smelled as if it were made from camphor or moth balls.

It was great stuff, and the film glided through the projector

with out a sound.

Let alone that this product was packaged in a red colored tin,

and was sold with a skull and cross bones

on the sticker label !

I have not soaked a print in Film Renew to test the integrity

of the splices after soaking, but have used Film Renew and

find that it is a quality product.

Film Renew is similar to Vita Film, but without the strong odor.

Vita film is available again.

Hope this helps and is not confusing.

It's all a matter of trying it out,

but it's good to inquire first.

Until another time.

Michael

--------------------

Isn't it great that we can all communicate about this great

hobby that we love!

| IP: Logged

|

|

|

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic

![[Frown]](frown.gif)

![[Big Grin]](biggrin.gif)

![[Smile]](smile.gif)

![[Mad]](mad.gif)

![[Wink]](wink.gif)