|

Author

|

Topic: Another Part for Edwin

|

Paul Adsett

Film God

Posts: 5003

From: USA

Registered: Jun 2003

|

posted March 17, 2015 12:33 PM

posted March 17, 2015 12:33 PM

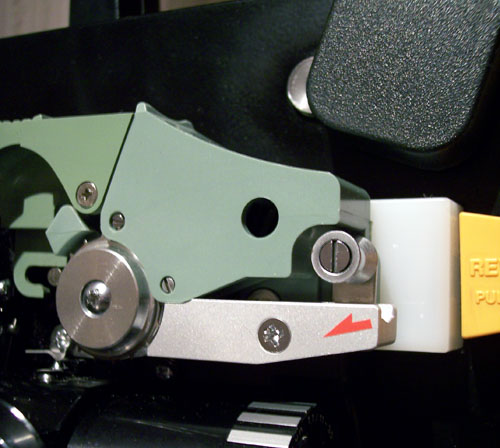

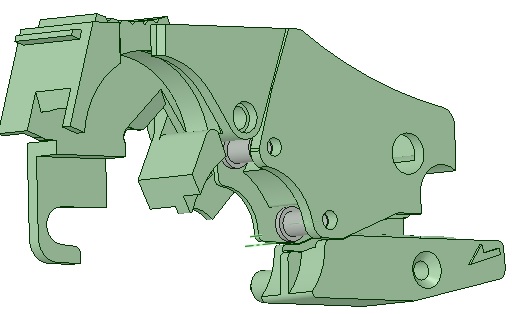

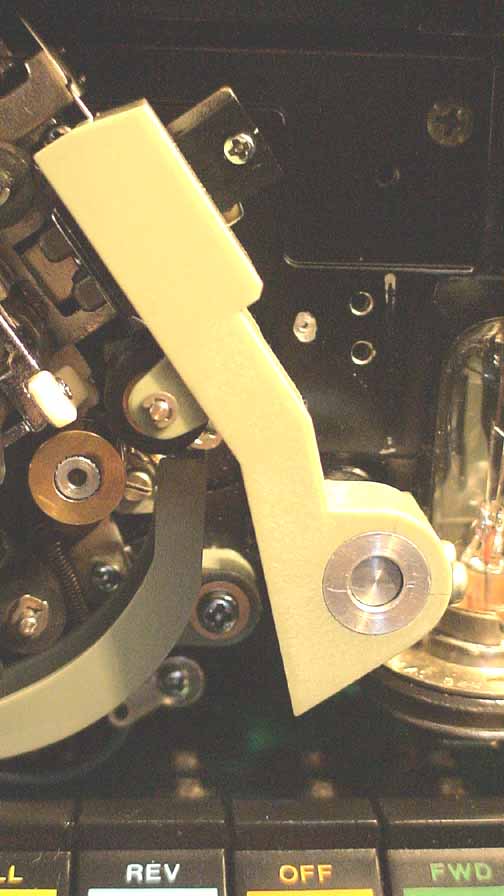

Here is another part for manufacturing consideration by Edwin's company.

It is the sound roller pressure arm of the GS1200. It serves to mount the rubber pressure roller which bears down on the sound capstan. It is made from hard plastic material, with a metal boss pressed in where it attaches to the solenoid shaft. The boss has two metric threads for inserting and tightening two grub (set) screws.

As manufactured by Elmo these arms have a common problem of cracking around the metal boss. This loosens the arm a bit, resulting in lowered pressure on the rubber capstan roller, and WOW distortion of the sound.

If Edwin were to remanufacture this part, there is no reason he could not beef up the wall thickness of the plastic around the boss to correct the cracking problem. Indeed he could sustantially taper that sharp corner where the profile of the hub intersects the arm feature, which would really stiffen up the arm considerably. No area of this part touches the film, and a superior part finish is not necessary, except the two little holes which locate the metal shaft of the rubber roller, which may have to be precision drilled.

[ March 17, 2015, 01:56 PM: Message edited by: Paul Adsett ]

--------------------

The best of all worlds- 8mm, super 8mm, 9.5mm, and HD Digital Projection,

Elmo GS1200 f1.0 2-blade

Eumig S938 Stereo f1.0 Ektar

Panasonic PT-AE4000U digital pj

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic

![[Razz]](tongue.gif)