|

Author

|

Topic: Inventing a projector

|

|

|

|

|

Paul Browning

Phenomenal Film Handler

Posts: 1006

From: West Midlands United Kingdom

Registered: Aug 2011

|

posted December 13, 2015 09:59 AM

posted December 13, 2015 09:59 AM

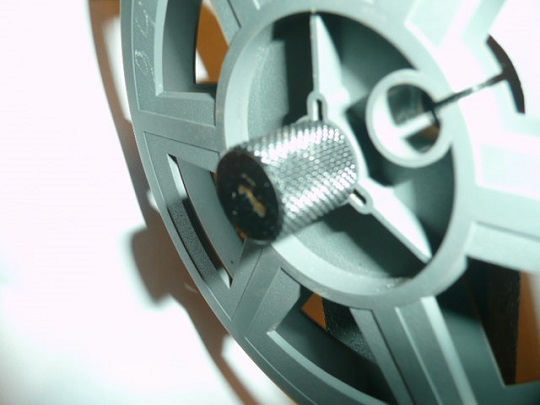

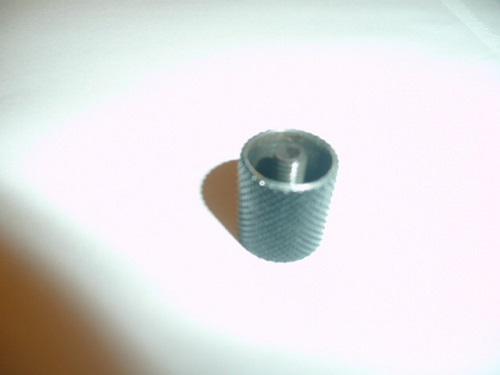

Hi Phil, you lost me a bit here, are you saying the hub is a knurled screw on part, a threaded separate part. This would make more sense really, as for using air cans, well once held in the hand for a few minutes, the compressed air that suppose to come out turns into water vapour, not a good idea around film guides or film for that matter, only used one once, waste of time and money. A set of artist brushes modified with sable hair or bristles are better and cheaper. The guide I refer to phil, is flat, it has no relief in the middle, so if the film comes into contact with it, it will touch the film across the full width, I suggest you look at this again, and if anything check for wear. This looks very similar to a part on the Elmo gs 1200 that should be modified, a front top guide that turns the film upward and over the top cog when lacing up the projector, it wears very flat and scratches the film, a don't believe the plastic on the beaulieu is of better quality, its something I will be changing on mine soon.

| IP: Logged

|

|

Andrew Woodcock

Film God

Posts: 7477

From: Manchester Uk

Registered: Aug 2012

|

posted December 13, 2015 10:45 AM

posted December 13, 2015 10:45 AM

Paul, the only plastic guide that stays anywhere near the running film once threaded on the Beaulieu, is the top sprocket lower input guide with an adjusting screw fitted to it.

This has to stay in close proximity to the film to allow the loop to be continually formed, and secure the film sprocket holes within the actual sprocket.

It has to be set to two acetate film thicknesses in order to ensure it cannot harm your prints.It has a tiny set screw fitted to the inside of this guide to allow for this adjustment.

If this is adhered to, no scratch problems occur from these. They are renowned for having a very precise non scratch film path when everything is how it should be.

I occasionally use compressed air on my film gate to thoroughly clean inside and out. It gives a much cleaner film frame after these occasional interventions, but you do have to allow time for steel guides to return to room temperature before refitting the lamp and lens I find.

For everyday use, I also use a photographic soft blower brush as well as a short stubby firm brush for cleaning the fixed side of the gate aperture plate.

I have not experienced any problems with excessive moisture if the can is inverted and given a quick burst prior to using on the projector.

These machines,I find, do tend to pick up every stray particle or fibre in the air just because of its open gate design.

The Fumeo has the better idea I reckon by having a similar open swing gate design, but then gives it its own independent cover for the gate besides the ones they both have for the lamphouse.

This would further reduce the claw noise as well as protecting the gate more fully from the ingress of atmospheric particles had the Beaulieu design featured the same.

A clip on neoprene lined fitted removable cover around the gated area would give these machines a further improvement I feel, while we are reinventing the wheel here! ![[Big Grin]](biggrin.gif) ![[Smile]](smile.gif)

[ December 13, 2015, 01:49 PM: Message edited by: Andrew Woodcock ]

--------------------

"C'mon Baggy..Get with the beat"

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Barry Fritz

Phenomenal Film Handler

Posts: 1061

From: Burnsville, MN, USA

Registered: Dec 2009

|

posted December 13, 2015 10:22 PM

posted December 13, 2015 10:22 PM

In practice, not very often Andrew. Still, when I have needed to with autos, it can be a pain. Also, auto need to have the starting tip of the leader trimmd in a particular way and if the tip has a tendency to curl a bit due to prolonged time on the reel, that will cause problems also. Lastly, as someone mentioned earlier, the catching of the film by the take up reel is sometimes hit and miss. Slot loaders have none of those problems.

| IP: Logged

|

|

|

|

|

|

Barry Fritz

Phenomenal Film Handler

Posts: 1061

From: Burnsville, MN, USA

Registered: Dec 2009

|

posted December 14, 2015 09:39 AM

posted December 14, 2015 09:39 AM

Phil, Paul:

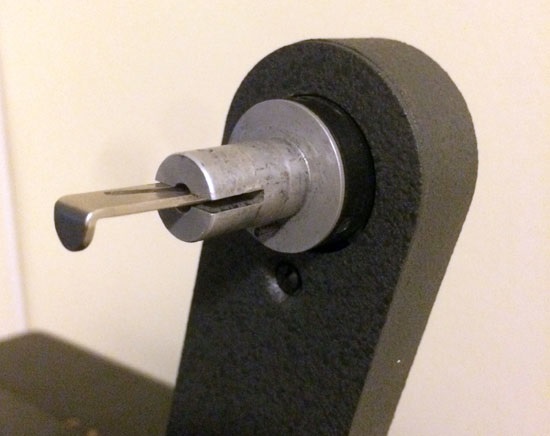

Actually, slot loaders are not manual threaders. You just put the film in the slot and turn the machine on. With manual threaders, you do have to go over each sprocket and lay the film in the film gate correctly, making sure upper and lower loop are correct. Even so, as Phil said, the design of the Bolex 18-5 with the swing open gate is perfect. Very, very easy and almost foolproof. I don't think I ever saw a slot loading 8 or super 8mm projector. Here is a 16mm slot loader.

| IP: Logged

|

|

|

|

|

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted December 15, 2015 02:26 PM

posted December 15, 2015 02:26 PM

An other idea.......

"Making up from start to finish" a new design projector couln't be the job of a man alone. Many different specialties are involved in the Job, as Basic Mehanic, Electronic, Cinematic, Optical, Design, etc...etc.

There are some specialists for each of them, anybody can have skills or ideas to bring , whether he is a specialist or not.

Aim should be to put the Super 8 machine in the current age , taking benefit of the best technologies available . Just an Exemple :

It should be great that the New machine features a "Malt Cross" film driving System. This is an expensive system to releaze due to precision requested for each item entering composition.

(I choose this exemple assumming Claw system or "Malt Cross" system is a strategic item.)

Now, imagine same device made around an Electronic "Malt Cross", whith no more "malt cross" necessary in fact :

Just a "Step to Step" Motor joined to an electronic regulated motion.

Now, is it safe enough, at first glance no ? and you are right...

Exept you just need a Triple Chanel Electronic Pilot Module.

Each Chanel is speaking with each others, comparing their datas in the same time. One Channel is the Master. If any Channel doesn't agree, it is immediatly put on the side, the others Chanels working properly, your machine keeps running perfectly , without any change.

This kind of concept is common now for professionnal sytems.

That it wasn't possible to do in the past for reasonnable money, is possible now.

Phil

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic

![[Big Grin]](biggrin.gif)

![[Smile]](smile.gif)